“At Mikrodust we develop complete test fixtures for customers used primarily for Functional-Circuit-Test (FCT). Other uses include tests such as In-Line-Test and Final-Assembly-Test, depending on requirements. The production test equipment is responsible for testing the target device per the test specification.

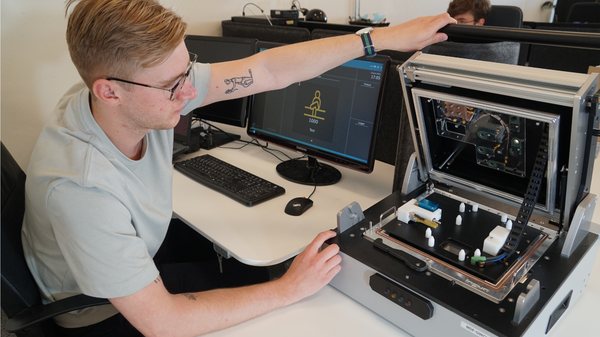

Mikrodust bases all test fixtures on the AtoMik®Platform. The Platform contains all parts necessary to deliver a high-quality fixture at the lowest cost. It includes hardware, software, and mechanics for handling single or multi-slot DUT (Device Under Test) configurations.

"AtoMik® - we bring quality to innovation”

At the heart of the AtoMik®Platform lies our in-house developed range of Instruments. The design results from over ten years of test fixture development for our customers. The goal was to replace the typical 19" test rack setup with a more cost-effective and reusable solution.

The compact size (5x9cm) allows mounting inside the fixture, for example, Ingun MA20xx series or MA21xx (RF shield). Other industry-standard test fixtures are also supported.

Connect power, Ethernet, a keyboard, and a monitor; you are good to go!

AtoMik® Instruments cover the majority of test cases needed for achieving a high-quality product. AC/DC tests, DAQ measurements, and programming/debugging supporting single or multi-slot DUT configurations.

Atomik® Instruments can be calibrated according to ISO 17025 standards by an accredited test house.

"Mikrodust - Inventor of AtoMik®"

Mikrodust test fixtures have tested more than 50 000 000 products since 2011. The majority contained radios and, in most cases, multiple radios at different frequencies. We know how essential software is!

At the core of AtoMik® Platform resides Mikrodust's proprietary Test Engine, ensuring test sequences execute according to test specifications. The Test Operator GUI allows the test operator to monitor the test progress and is alerted of any test failures. Custom factory test firmware can be used during the testing process.

Test fixtures used in production generate large amounts of data based on the agreed test specification. AtoMik® Platform connects to the cloud-based AtoMik® Portal and transfers the test data making it protected and secure. Test data is accessed and analyzed by logging on to the AtoMik® Portal.

Software updates, calibration, and preventive maintenance are remotely maintained to guarantee 24/7 test fixture operation. After passing the test, the application software is typically flashed onto the DUT, and the final product is ready to ship out to the customer.

AtoMik® - Quality Management made easy!

As with any testing, the ultimate goal is to identify and address defects or issues before the product reaches the customer and reduce the risk of product returns. The result? A high-quality product that meets or exceeds customer expectations. Using the AtoMik®Platform, You are one step closer to achieving that goal.

AtoMik®Platform and AtoMik®Portal ensure a high-quality test fixture with single or multi-DUT capabilities with remote 24/7 monitoring capabilities. With minor modifications, the test fixture stands ready for your next project.

Contact Mikrodust today and learn how AtoMik® can protect your brand value, maximize production yield, and reduce costs.

"AtoMik® - we bring quality to innovation"