Built for Speed.

Designed for Change.

Testing takes too long.

AtoMik® runs your cycles 5x faster.

Legacy test setups slow you down with high costs, long lead times, and static configurations. AtoMik® flips the model, offering a modular, developer-friendly platform that grows with your needs, integrates with your workflow, and gets you testing faster than ever.

Legacy system

33s / cycle

23%

Current step

Devices tested

0

7s / cycle

23%

Current step

Devices tested

0

Based on real-world case studies

Rethink your setup

Still testing like it’s 1987?

From oversized rigs to fragile cable nests and bloated software stacks, legacy setups often create more problems than they solve. They eat up space, are hard to maintain, and slow down every stage of your workflow.

You’re wasting valuable bench space on oversized gear

Scaling quickly gets expensive

Your setup is too bulky to move around

A modular test platform for faster setups and smarter workflows

AtoMik® is a compact, configurable test system made up of swappable instruments, a shared backplane, and intuitive control software. Designed to fit any stage of the product lifecycle, from R&D to production, AtoMik® helps your team move faster.

Modular architecture

Design a test environment that adapts to your product — not the other way around. AtoMik® modules connect seamlessly, so you can scale functionality without starting from scratch or overhauling your setup.

Test faster, iterate smarter

Unbox, plug in, and start testing sooner. AtoMik® dramatically shortens setup times so your team can shift focus from configuring complex tools to refining the final product. It’s test-ready when you are.

Sustainable efficiency

Achieve more with less. Each test

consumes less energy, uses fewer

fixtures, and leaves a smaller

footprint — delivering measurable impact without compromising

performance.

Compact footprint

Forget refrigerator-sized rigs and sprawling test stations. AtoMik® delivers precision results in a space-saving form factor, making high-performance testing accessible in any environment.

Platform overview

One System, Endless Possibilities

Combine our electronics with your preferred fixture and software to achieve a state‑of‑the‑art setup that shortens bring‑up and speeds every test cycle.

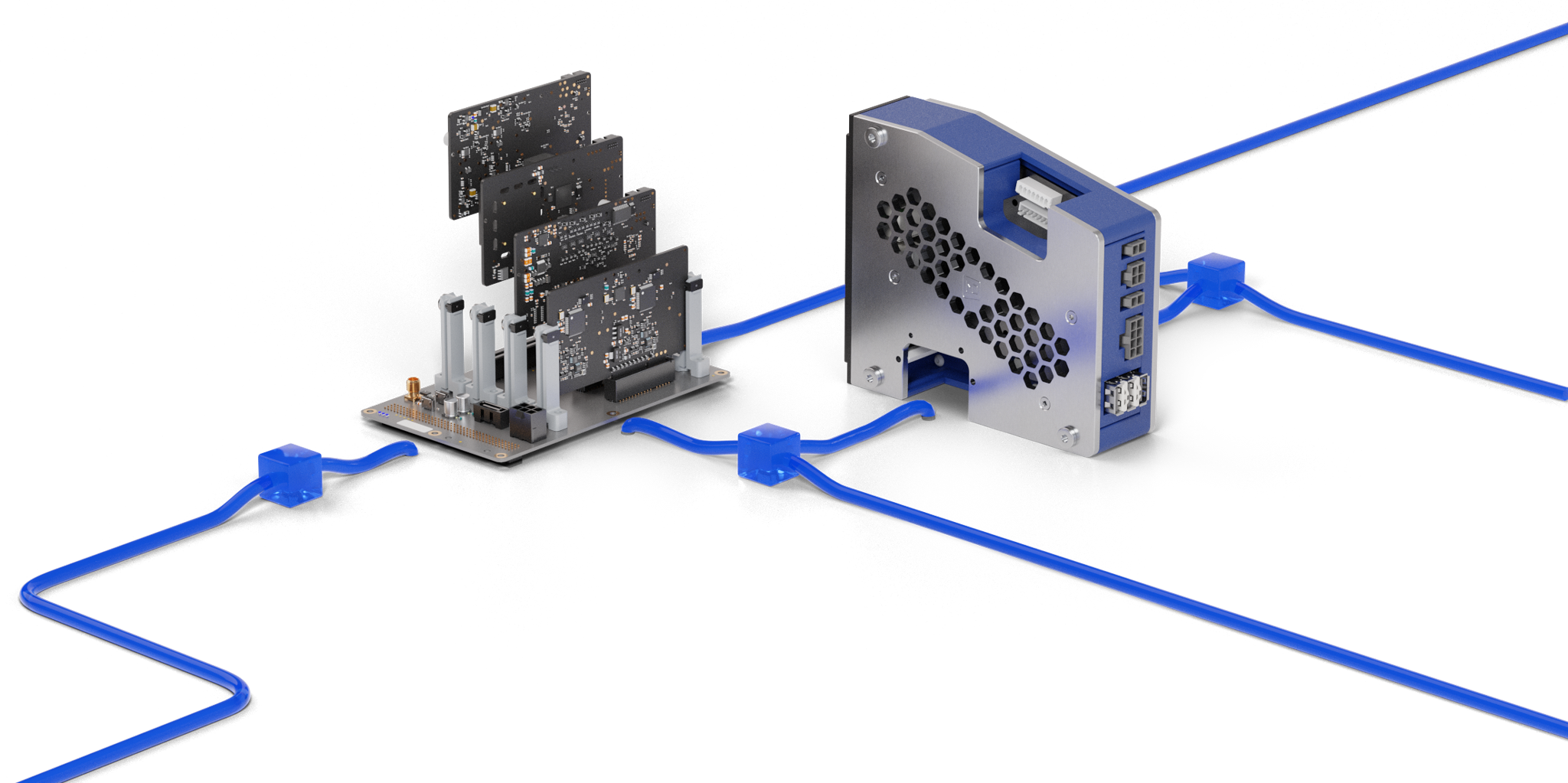

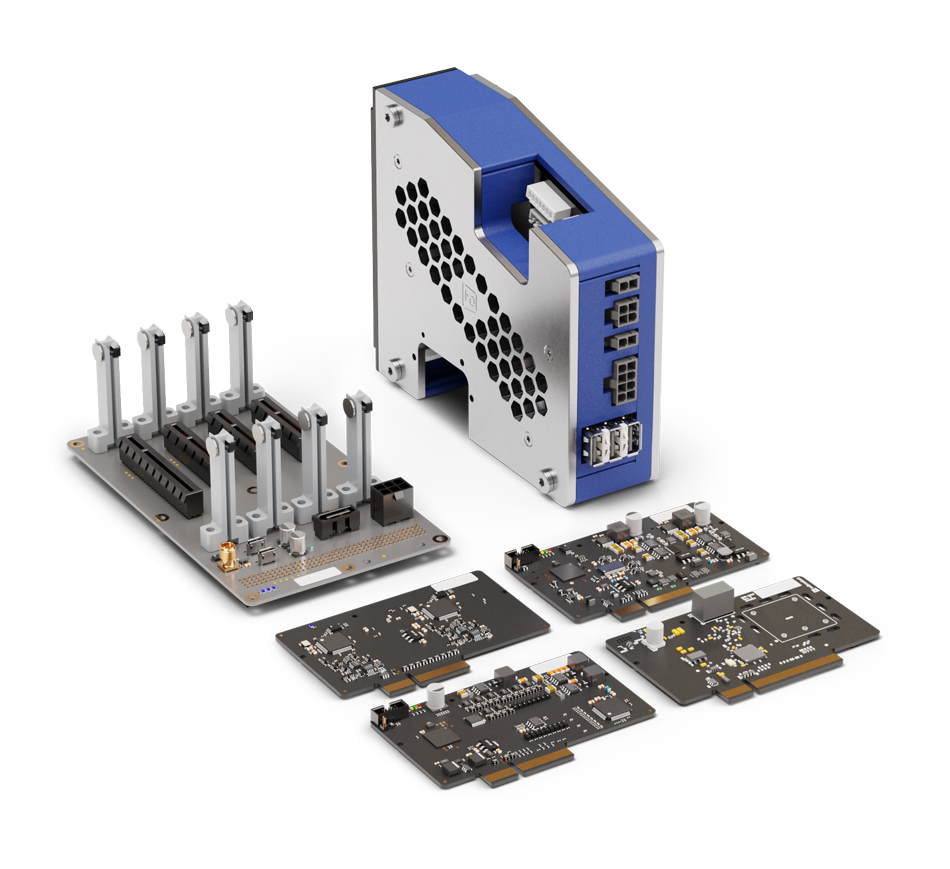

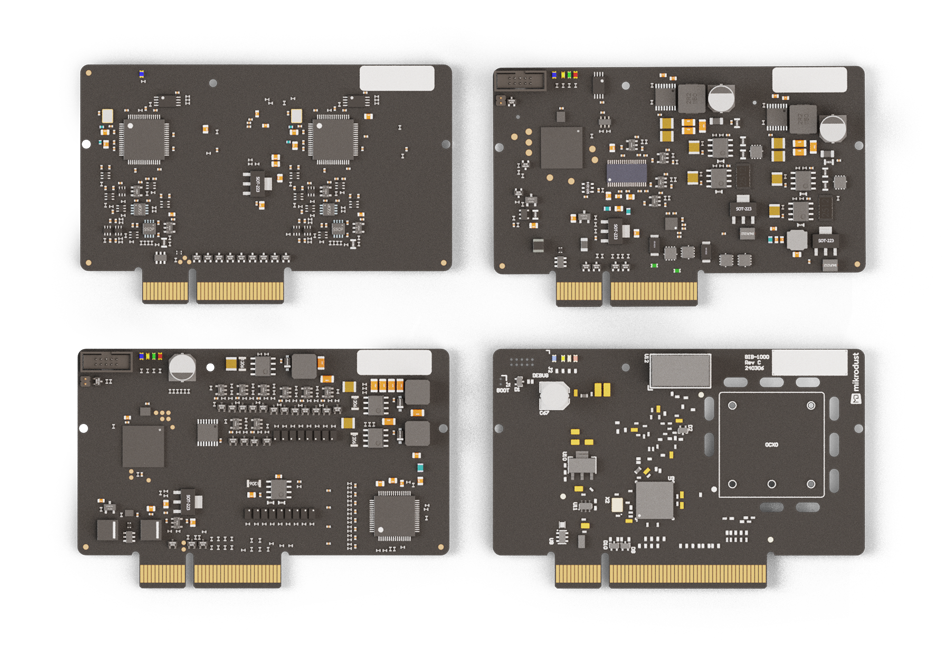

AtoMik® Products

At the core of AtoMiK® is a backplane and power module, into which you plug precision instruments tailored to your needs — DAQ, SMU, PRG, and more. Everything connects seamlessly through the developer tools, so your setup is both scalable and streamlined.

x4 Backplane

Interface Module

Instruments

+ Cables and accessories

Fixture frame of your choice

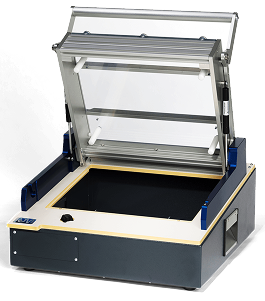

The compact size of AtoMik® allows for a complete test system to be installed within a standard fixture frame and it even fits inside an RF shielding box. We have taken the different market-leading fixture frame manufacturers into account, meaning that the system is compatible with the most common brands.

These examples represent just a subset of the fixture frames AtoMik® is compatible with.

Software of your choice

AtoMik® works with leading test-sequencing platforms. With the included AtoMik® Connector SDK, integrating with your preferred environment is easy and intuitive. The SDK gives you precise control over measurements while maintaining the user-friendliness AtoMik® is known for.

These examples represent just a subset of the test-sequencing platforms AtoMik® is compatible with.

A compact, modern test system — delivered your way.

How it all fits together

An adaptable and compact test fixture built with configurable, ready-made and off-the-shelf components and instruments.

Overview

AtoMik® Test System is an adaptable and compact solution built with configurable, ready-made and off-the-shelf components and instruments.

The compact design of AtoMik® Test System instruments (5x9cm) allows the fixture to be significantly smaller, saving valuable production space. This efficient use of space dramatically reduces the testing setup’s footprint.

The test engine is optimized for parallelized instrument measurements to increase productivity by faster test times.

Fixture Frame

Thanks to its compact form factor, AtoMik® enables complete test systems to be integrated directly into standard fixture frames — and even within RF shielding boxes when required.

Its compatibility with leading fixture frame brands gives you the freedom to choose a setup that fits your existing processes and preferences.

By selecting the fixture frame size and brand that best aligns with your product specifications, production volumes, and operational needs, you can achieve a cost-effective, space-efficient solution optimized for the full lifecycle of your product.

Interface

By leveraging rapid prototyping technologies like 3D printing and CNC machining, you can achieve a fast transition from CAD to fully customized mechanical interfaces — including pressure plates, support structures, and guide plates — all precisely tailored to the DUT’s geometry and layout.

A custom routing PCBA bridges the AtoMik® instrument interface to the DUT via test probes, ensuring reliable signal integrity and mechanical alignment — even in complex or space-constrained setups.

AtoMik®

The AtoMik® Instruments are connected to the routing PCBA via a connector. The system is modular so that every test case can be easily covered and optimized in the test system.

The Interface Module offers embedded pneumatic or electro-mechanical control for mechanical interactions during testing and allows for integration of 3rd party equipment such as RF frequency counters, generators, and power meters.

Accessories

Enhance usability, feedback, and test coverage

A range of optional accessories is available to extend the functionality and user interaction of the AtoMik® platform.

These include:

- Integrated barcode scanners for automatic serial number logging and enhanced traceability

- RGB push-buttons for intuitive visual feedback to the operator

- RF filters, switches, near-field antennas, light sensors, LED boards, and more – enabling coverage of both standard and specialized test cases

These add-ons help tailor your system not just to the DUT, but also to the operator and the testing process as a whole.

Computer

A computer is mounted on the backside of the fixture frame to control the test engine, provide the fixture with an internet connection, and ship production data to the cloud.

The computer also serves as the interface for a monitor, keyboard, and mouse pointer so that the operator can use the system efficiently.

RF Shield

An optional radio frequency shielding is available for when you need to test wireless communication, to protect the measurements from external interference and to protect the operators from frequency fields radiating from within the fixture.

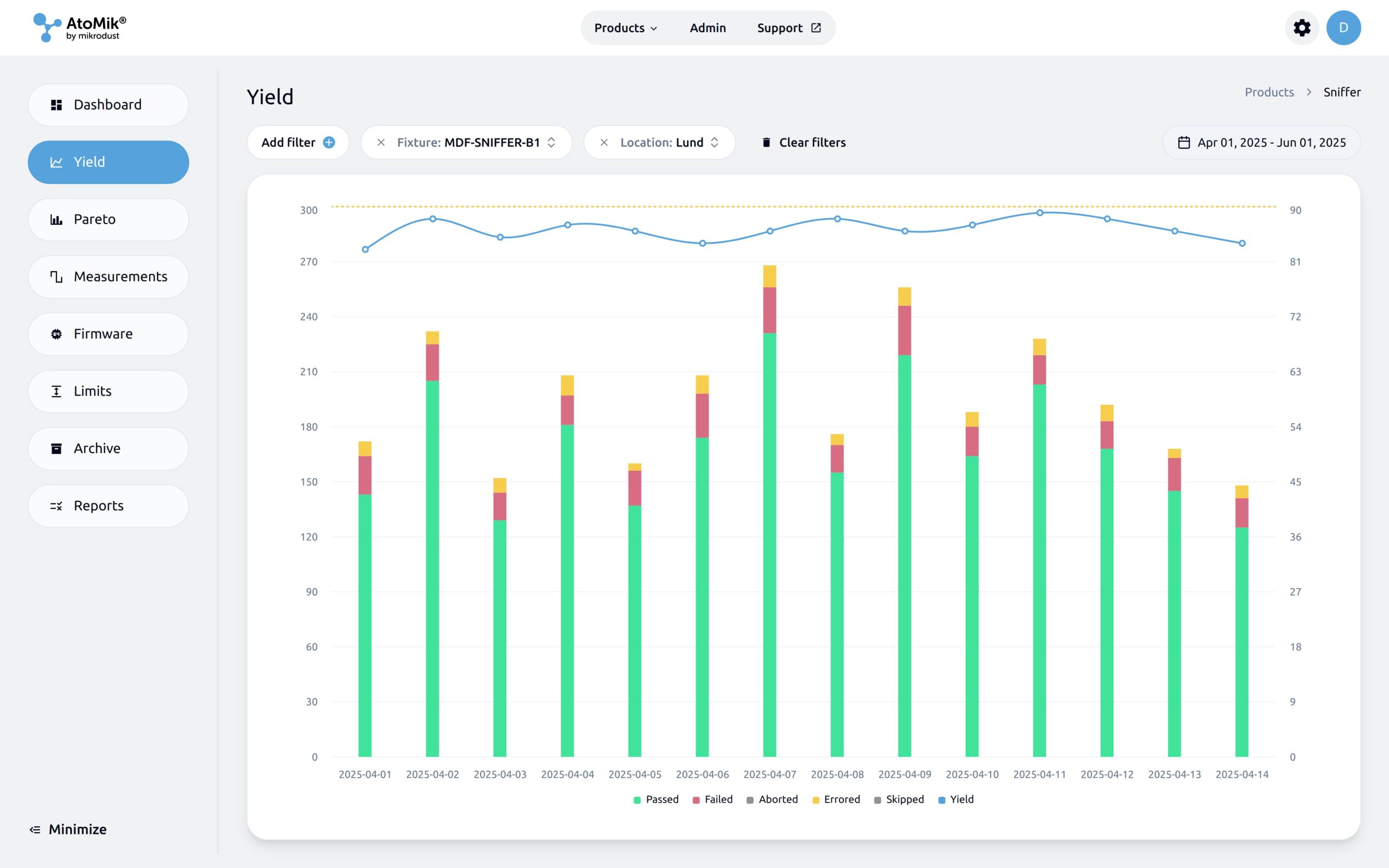

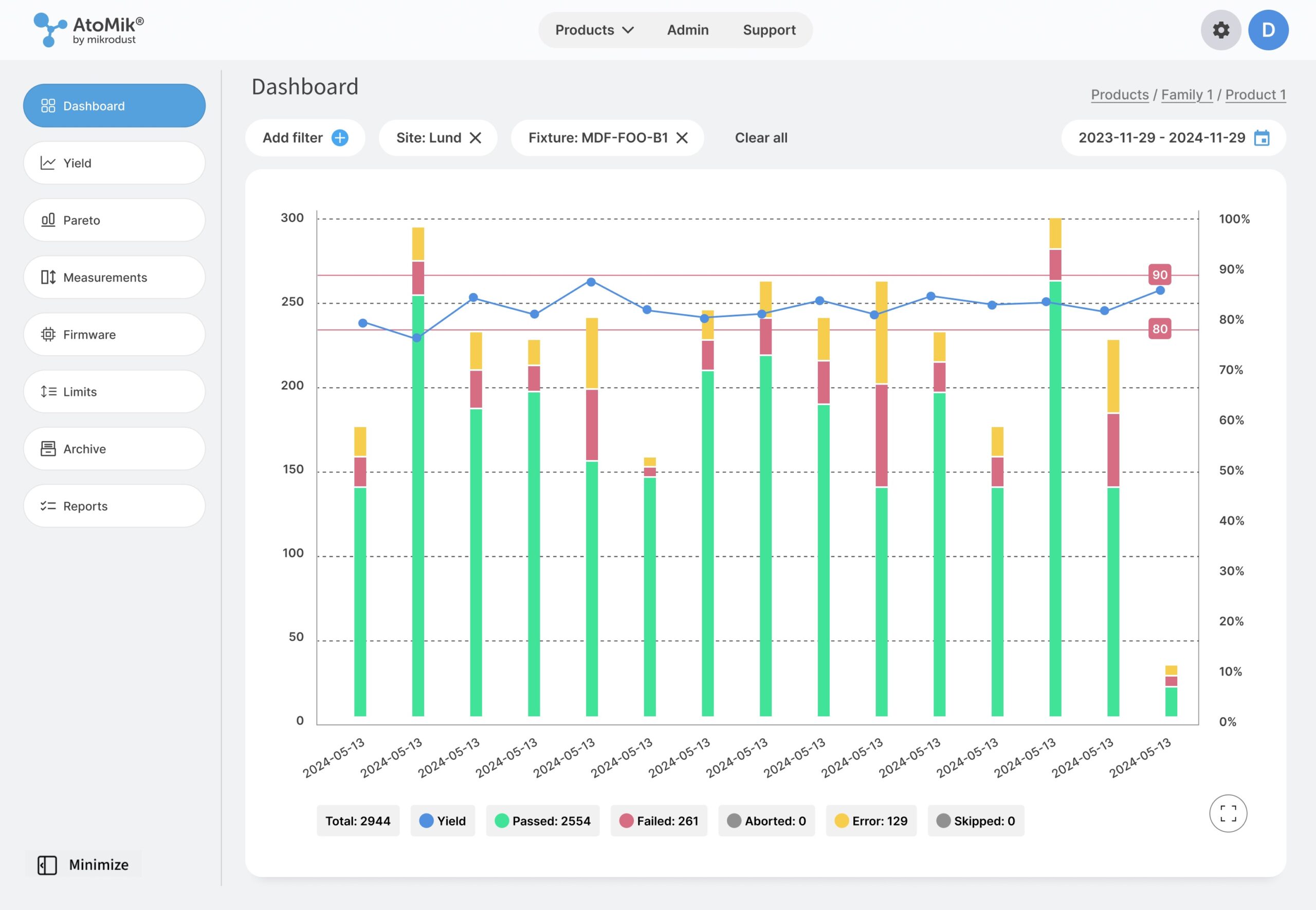

AtoMik® Cloud Portal

Remote access, real-time analytics, smarter decisions

The AtoMik® cloud platform connects every test cycle to a central analytics layer, helping you track results in real time and act quickly when it matters. Perform remote maintenance, collaborate with your test developers, and integrate with third-party tools to continuously refine performance.

Monitor test data in real time and spot issues before they scale

Perform remote maintenance and reduce downtime across sites

Collaborate with partners and integrate with your analytics stack

AtoMik® cloud analytics platform

Customer stories

Real results, from real production lines

From high-volume production lines to precision test environments, AtoMik® has helped companies cut cycle times by up to 75%, scale without rebuilding, and reduce maintenance overhead. These aren’t lab benchmarks — they’re results from real factories, real workflows, and real savings.

Case #1

Single-to-Dual Slot Transition

Europe

Background

The product is a home alarm gateway requiring multiple RF (radio frequency) tests, mechanical interactions, and electrical validation. A product update called for a new test fixture, prompting a switch from legacy equipment to AtoMik®.

Baseline

Their previous traditional test system ran single-unit tests with a 400-second cycle time. This setup limited throughput and required a full rebuild to scale.

Using AtoMik®

AtoMik® enabled a dual-slot fixture, running nearly the same test sequence in 220 seconds — testing two units in almost half the original time. The result: double the output with significantly faster cycles, lower maintenance, and a future-ready setup built for scaling.

Reduction in test time

72.5%

Case #2

High-Volume Production Line

China

Background

A leading global manufacturer of wireless and corded communication equipment, specialized in videoconferencing. They sought to reduce test cycle times to minimize handler count, save space, and cut maintenance and production costs.

Baseline

The setup relied on 19” rack-mounted instruments and a legacy sequence. Testing 2 devices per cycle took 33 seconds.

Using AtoMik®

By transferring the same sequence to the AtoMik® test engine and reusing their existing automated fixtures, the cycle time was reduced to just 7 seconds — a 78,8% improvement. This upgrade doubled throughput while preserving infrastructure, dramatically increasing test capacity without added complexity.

Reduction in test time

78.8%

Sector Alarm

“We’ve had a close, solution-oriented collaboration with Mikrodust, who’ve shown a strong understanding of our technical and logistical requirements. Their test solution is both robust and flexible — exactly what we need as we scale our growing production in Europe.”

— Leif Motrø, CTO and Co-Founder of Sector Alarm.

Regin AB

“Regin partnered up with Mikrodust a few years ago when introducing wireless products that needed a new test system in production. This new test system is flexible with a cassette system making it possible to test different products efficiently in the same base unit. We have a very good experience in our cooperation with Mikrodust and value their expertise and accountability.”

— Mats Falk – Manager and Change Leader

Note Lund AB

“Note Lund creates competitiveness for customers by delivering the right quality at the right time and at the right price. With world-class quality assurance tools, manufacturing methods and partners such as Mikrodust and their expertise in production test we ensure that customers know that we live up to our watchwords “right from the start”.

— Henrik Andersson – CEO

Services

Partnering with

Clients from Planning

to Production

We understand the complexity of the whole process and give you a tailored solution that meets each project’s specific needs and goals. By involving us early in the project, you benefit from our comprehensive understanding of test strategy, test specifications, and Design-For-Testability (DFT) analysis.

Built for modern product teams

Say goodbye to oversized systems and outdated workflows

Legacy test setups come with baggage — large footprints, slow deployment, steep learning curves. AtoMik® breaks from tradition with a focused, compact, and cost-efficient platform that’s easier to use, easier to scale, and significantly faster to deploy.

| Legacy systems | AtoMik® | |

| Setup time | Weeks | Minutes |

| System size | Large rack systems | Compact backplane |

| Cost | High upfront cost + licensing | Low-entry, scalable |

| Modularity | Fixed configuration | Fully modular |