Modern Components.

Unbeatable Speeds.

Interface Module

The Interface Module supplies regulated +24V and +5V power to AtoMik® instruments and auxiliary devices. It handles host communication via dual USB 2.0 ports, features a built-in USB hub with an RTOS-powered MCU, and supports external I/O including E-stop, RGB LED buttons, and displays.

Key Features

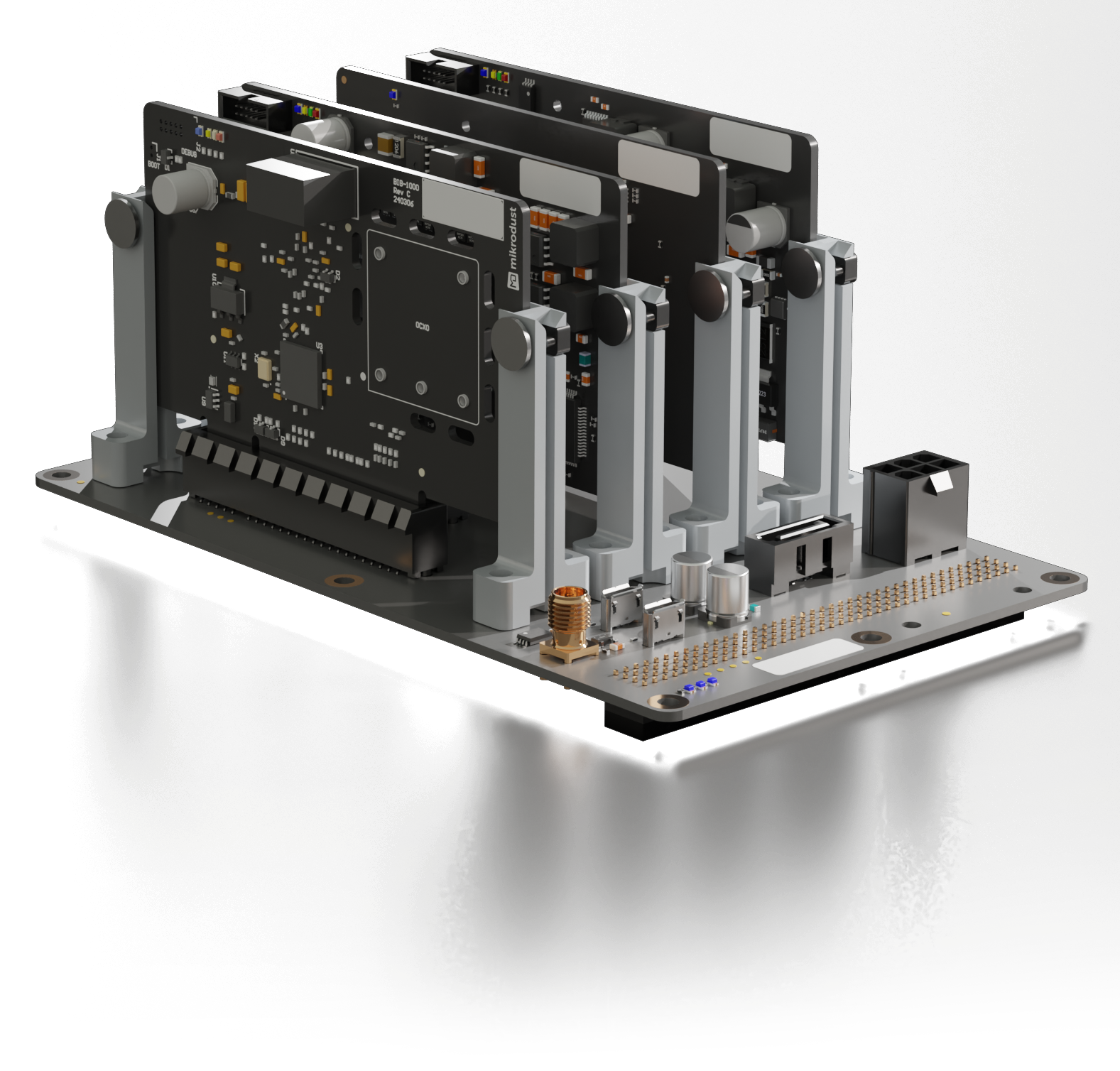

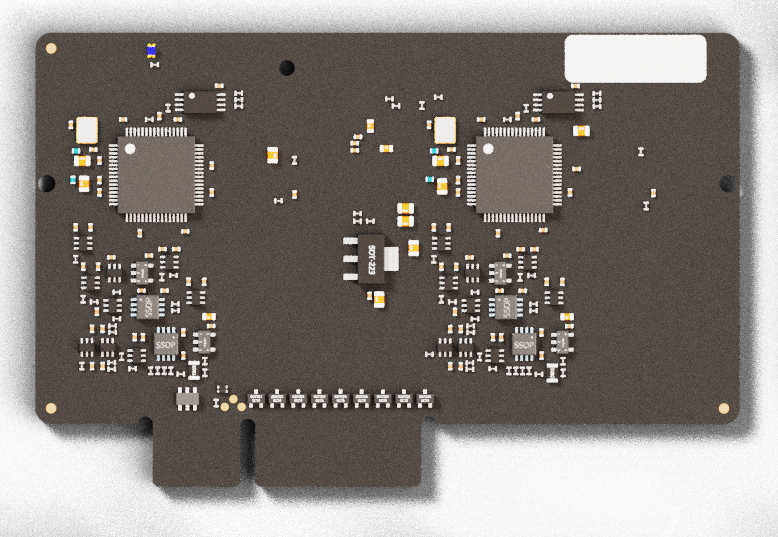

Backplane

This Backplane x4 populated with an AtoMik® BAS Instrument, up to three AtoMik® Instruments and together with USB 2.0 and power connection from an AtoMik® Interface Module creates a full featured, powerful and compact test and measurement system.

Different types of expansion such as two USB 2.0 channels and I2C/SPI interface is possible by utilizing the built-in expansion origin from an inserted AtoMik® BAS Instrument.

The offered 160 pin 2.0mm pitch connector test interface can easily be routed to targets in context of test fixtures, production test and R&D and product development.

Key Features

Instruments

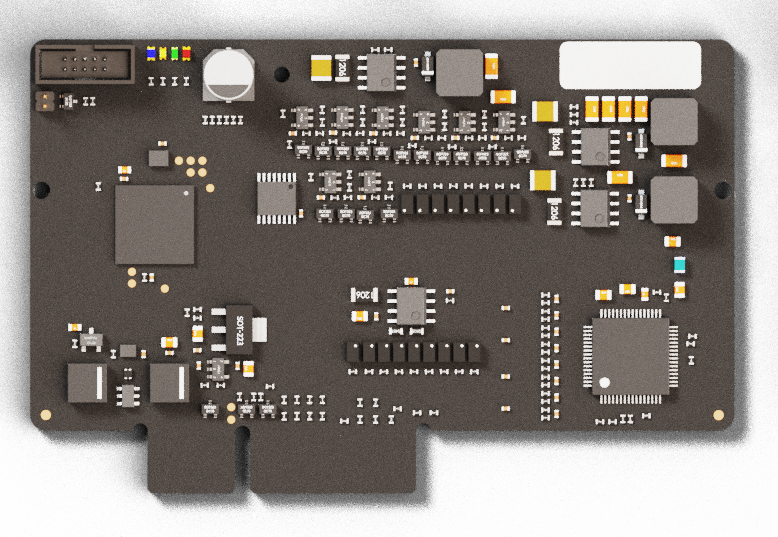

Source Measure Unit Instrument (SMU)

The SMU Instrument provides two high-precision software-controlled supply voltage channels with individual built-in software fuses.

Each channel offers configurable settings of slew rate and also remote sense voltage feedback with possibility to increase voltage accuracy. Current can be measured in 3 different ranges (mA, uA, nA) with high precision configured manual or in automatic mode. Different types of external expansion such as number of power supply channels is possible by utilizing the built-in expansion interface.

Key Features

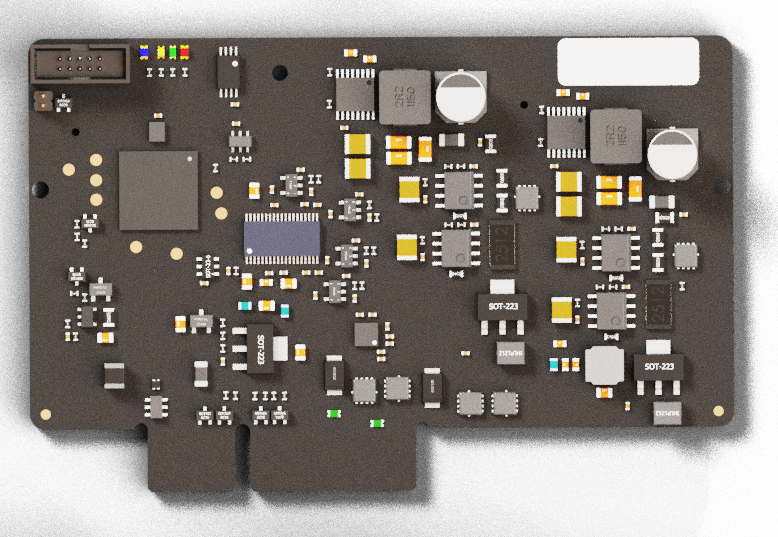

Data Acquisition Instrument (DAQ)

The DAQ Instrument provides high-precision data acquisition and converts real-world signals to the digital domain for display, storage, and analysis.

The instrument offers external connection to 16 single-ended analog input channels (AI) with a successive approximation ADC, two analog output channels (AO), 8 digital Push-Pull I/O channels (DIO). Each group of analog input channels AI0-7 and AO8-15 provides simultaneous sampling. All digital channels can be used as a counter. Different types of external expansion such as number of analog and digital channels are possible by utilizing the built-in expansion interface.

Key Features

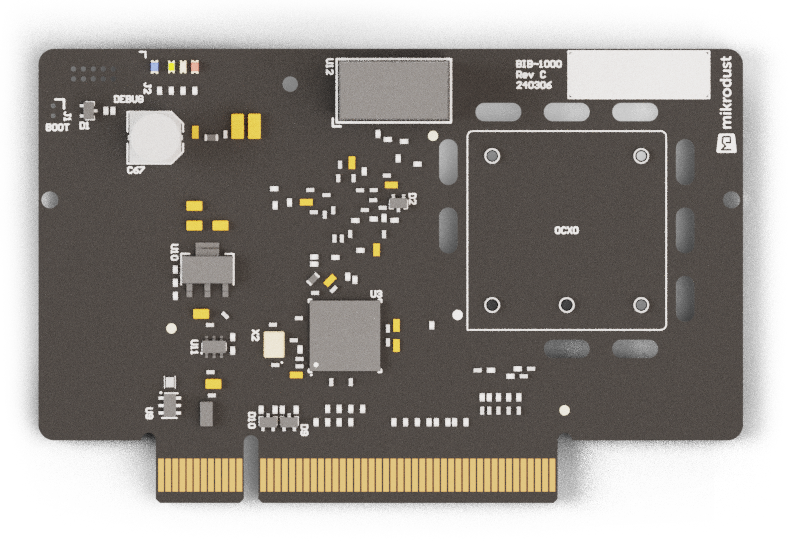

Base Control Instrument (BAS)

The BAS Instrument is the link between an external host computer and additional test instruments.

The instrument includes a USB hub to expand an incoming USB channel from an external host to an additional six test instruments. It also provides power enable and reset signals for up to six instruments. Various types of external expansion are possible through the built-in expansion interface.

Key Features

Programmer Instrument (PRG)

The PRG Instrument offers JTAG/SWD interfaces that act as bridges between the host and targets where the host communicate with targets utilizing the well-known open source OpenOCD software.

It implements a USB hub for expanding an incoming USB 2.0 channel to four USB 2.0 channels supporting four independent classic JTAG/SWD programming and debugging interfaces.

The PRG Instrument also contains four separate UART interfaces for e.g. communication with the test object from the host PC.

Key Features

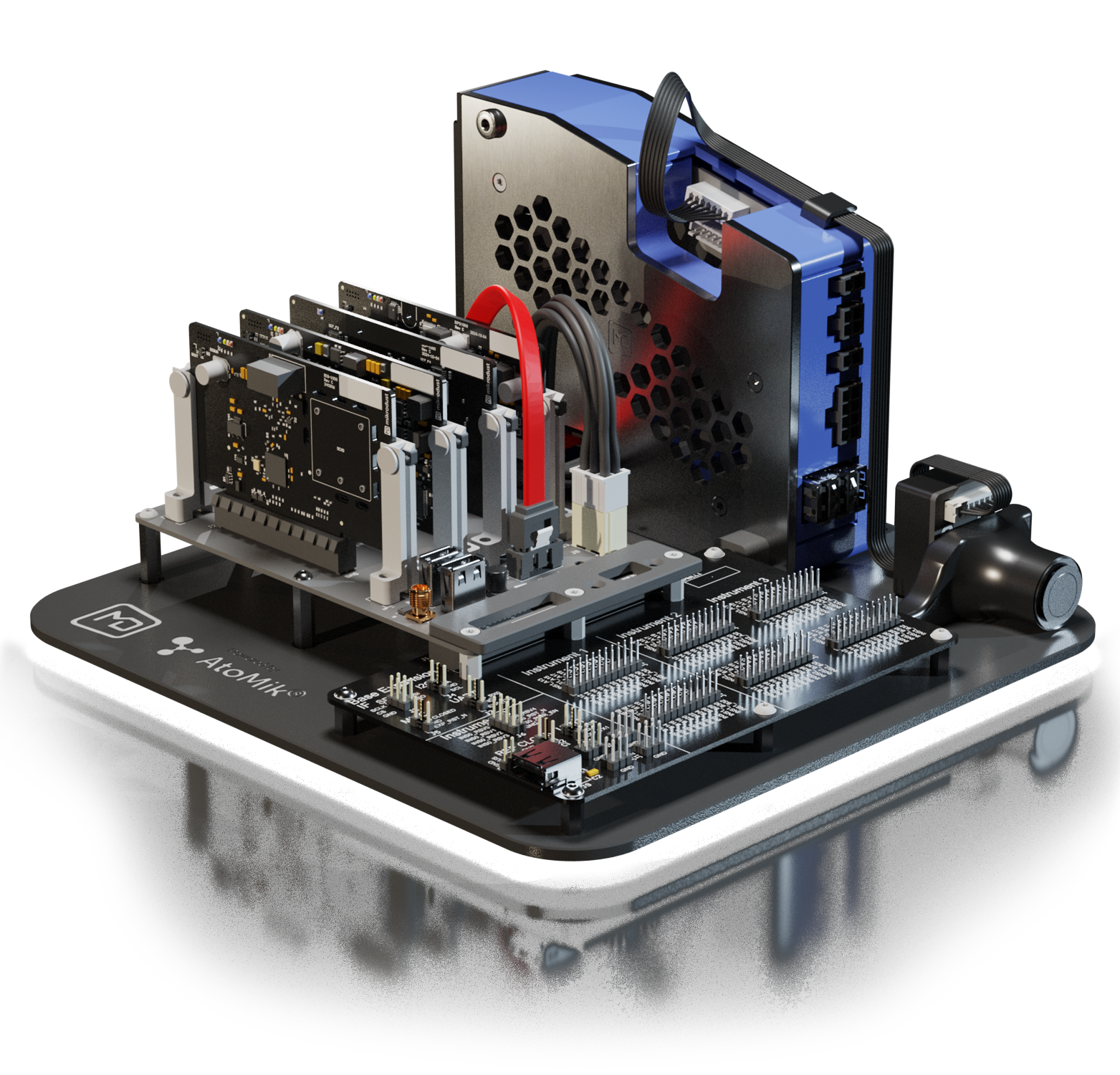

AtoMik® Dev Kit

A breakout board provides clearly labeled pin headers for each module, offering access to every functionality in the AtoMik® Ecosystem. The Dev Kit provides a modular instrument setup, ideal for test engineers wanting to evaluate the Atomik platform or develop test sequences.